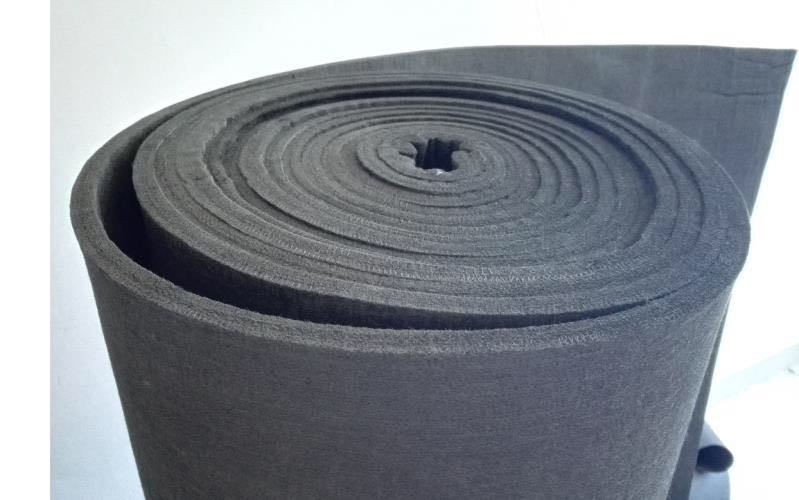

XINGSHI -Graphite Felts (Carbon Felts) Products information :

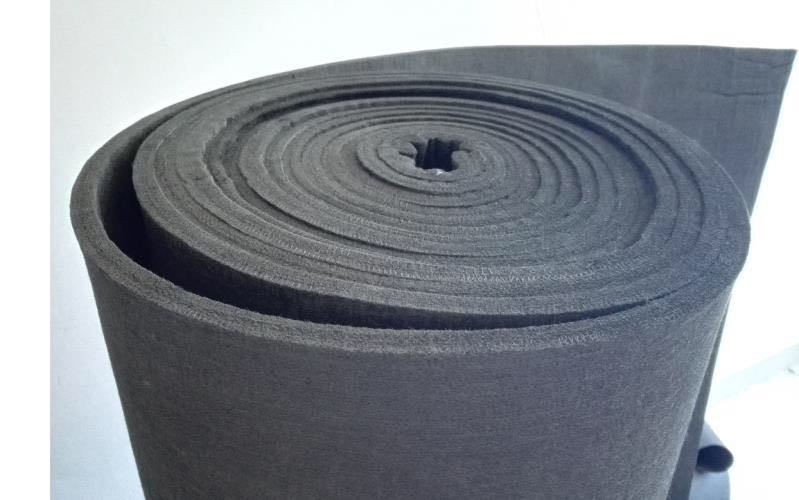

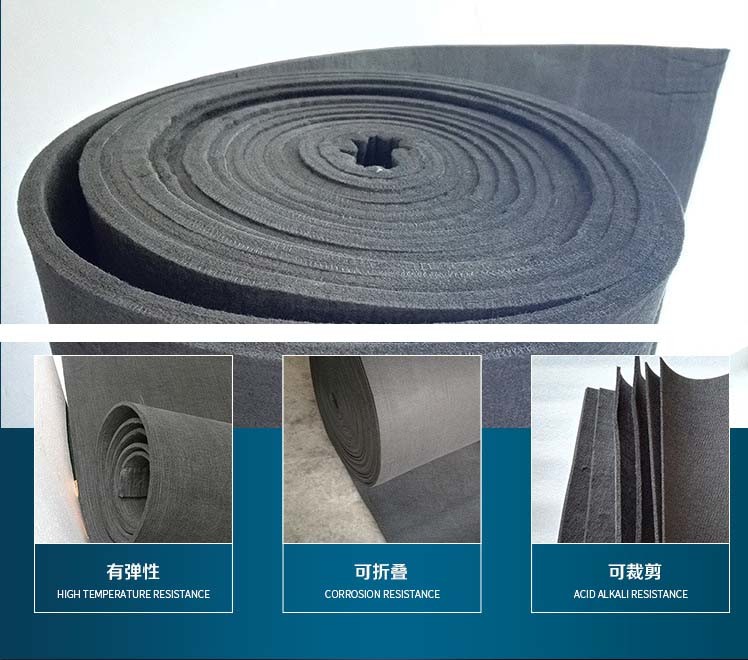

Insulation graphite fiber felt

Application :

1. Aerospace industry for adiabatic materials

2. Thermal Insulation materials for ultra high temperature vacuum metallurgy equipment and other composite maaterials .

3.It can also be used in high performance far infrared heating elements

For the graphite products,We have mold graphite,isostatic graphite,extruded graphite,vibration graphite. bulk density from 1.6g/cm3 to 1.91g/cm3.

Carbon-graphite products for electron and semiconductor industry

Carbon-graphite products for application of processing by industrial furnace under high temperature;--

Carbon-graphite products for sintering mold of diamond tools Carbon-graphite products for non-ferrous metallurgy and processing;

Carbon-graphite products for mechanical industry;

Carbon-graphite products for high-tech field

Carbon-graphite products for EDM

Carbon-graphite products for aviation and aerospace industry.

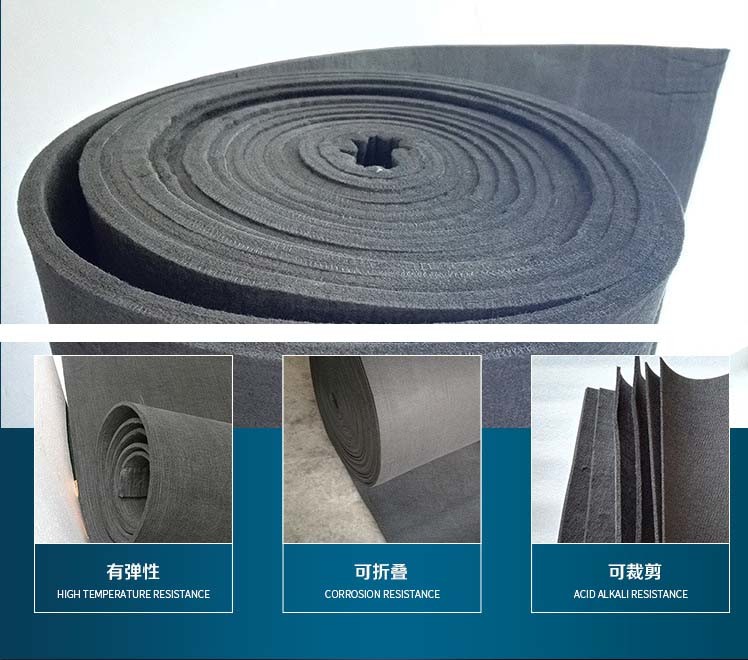

Graphite Felts - Characters

Why Choose Us ?

Products Advantages:

Insulation graphite fiber felt

Specification Sheet

Material | PAN-CF | |

Bulk density | 0.13 g/cm3 | |

Carbon | ≥99.9 % | |

Thermal conductivity | 0.12-0.16(1150ºC, W/m .k) | |

Tensile Strength | 0.14(Mpa) | |

Crushing stress at 10% compression | 8-10( N/cm2) | |

Ash | ≤0.02% | |

Processing temperature | 2300ºC | |

Operating Condition | In the air | ≤350ºC |

In the vacuum | ≤2300ºC | |

In the inert atmosphere | ≤3200ºC | |

Spec | Lenght (m) | 10 - 20 |

Wide (mm) | 1000-1400 | |

Thickness (mm) | 3,5,6,8,10,12 | |

Application :

1. Aerospace industry for adiabatic materials

2. Thermal Insulation materials for ultra high temperature vacuum metallurgy equipment and other composite maaterials .

3.It can also be used in high performance far infrared heating elements

The carbon felt is a graphite felt after being treated at a high temperature of 2000ºC or higher under a vacuum or an inert atmosphere,and the carbon content is higher than that of the carbon felt ,and is more than 99% .In addition to the high purity ,high temperature resistance ,corrosion resistance and non-melting properties of the graphite ,,the graphite felt has the advantages of elasticity ,arbitrarily folded ,cut and stiched with graphite yarn .The main purpose of graphite felt is as insulation and graphite yarn .The main purpose of graphite felt is as insulation and heat insulation material for single crystal silicon smelting furnace . It can be used as filter material for high purity corrosive chemicals in the chemical industry .The graphite felt can be used at a temperature of about 3000ºC under a non-oxidizing atmosphere .

Item | Index | ||||

No. | RCF Carbon fiber Felt | RCF Graphite fiber felt | PAN Carbon fiber felt | PAN Graphite Fiber felt | |

Material | RCF | RCF | PAN-CF | PAn-CF | |

Bulk Density(g/cm3) | 0.10-0.12 | 0.08-0.10 | 0.14-0.17 | 0.12-0.14 | |

Carbon (%) | ≥98.5 | ≥99 | ≥98.5 | ≥99 | |

Fhermal Conductivity (1150 ºC)' | 0.08-0.15 | 0.06-0.14 | 0.12-0.18 | 0.08-0.14 | |

Tensile strength Mpa | 0.13 | 0.1 | 0.15 | 0.14 | |

Crushing stress at 10% compression (N/cm3) | 6-10 | 5-8 | 8-12 | 8-10 | |

Ash% | ≤0.05 | ≤0.005 | ≤0.05 | ≤0.005 | |

Processiong Temperature(ºC) | 1200 | 2500 | 1200 | 2500 | |

Operating Condition | In the air | ≤400 | ≤400 | ≤400 | ≤400 |

in the vacuum | ≥1500 | ≥2200 | ≥1500 | ≥2200 | |

in the inert gases | ≥1800 | ≥2500 | ≥1800 | ≥2500 | |

Spec Dimension | Length | 16-18 | |||

width | 1000-1300 | ||||

Thickness | 3,5,8,10 | ||||

Normal Specifications :

Item | Index | ||

NO. | PAN Carbon felt | PAN Graphite felt | |

Density(g/cm3) | 0.14-0.17 | 0.12-0.14 | |

Ash(%) | ≥98.5 | ≥99 | |

Thermal Conductivity(1150ºC)(W/m.k) | 0.12-0.18 | 0.08-0.14 | |

Tensile Strength(Mpa) | 0.15 | 0.14 | |

Compression 10% Compression Stress (N/cm2) | 8-12 | 8-10 | |

Ash(%) | ≤0.05 | ≤0.005 | |

Processing Temperature(ºC) | 1200 | 2500 | |

Working Environment | Air(ºC) | ≤400 | ≤400 |

Vacuum(ºC) | ≥1500 | ≥2200 | |

Inactive Gas(ºC) | ≥3200 | ≥3500 | |

Descriptions | Length(m) | 12-15m | |

Width(mm) | 1.2m/1.4m | ||

Thickness(mm) | 8-15 | ||

For the graphite products,We have mold graphite,isostatic graphite,extruded graphite,vibration graphite. bulk density from 1.6g/cm3 to 1.91g/cm3.

Carbon-graphite products for electron and semiconductor industry

Carbon-graphite products for application of processing by industrial furnace under high temperature;--

Carbon-graphite products for sintering mold of diamond tools Carbon-graphite products for non-ferrous metallurgy and processing;

Carbon-graphite products for mechanical industry;

Carbon-graphite products for high-tech field

Carbon-graphite products for EDM

Carbon-graphite products for aviation and aerospace industry.

Graphite Felts - Characters

Why Choose Us ?

Products Advantages: