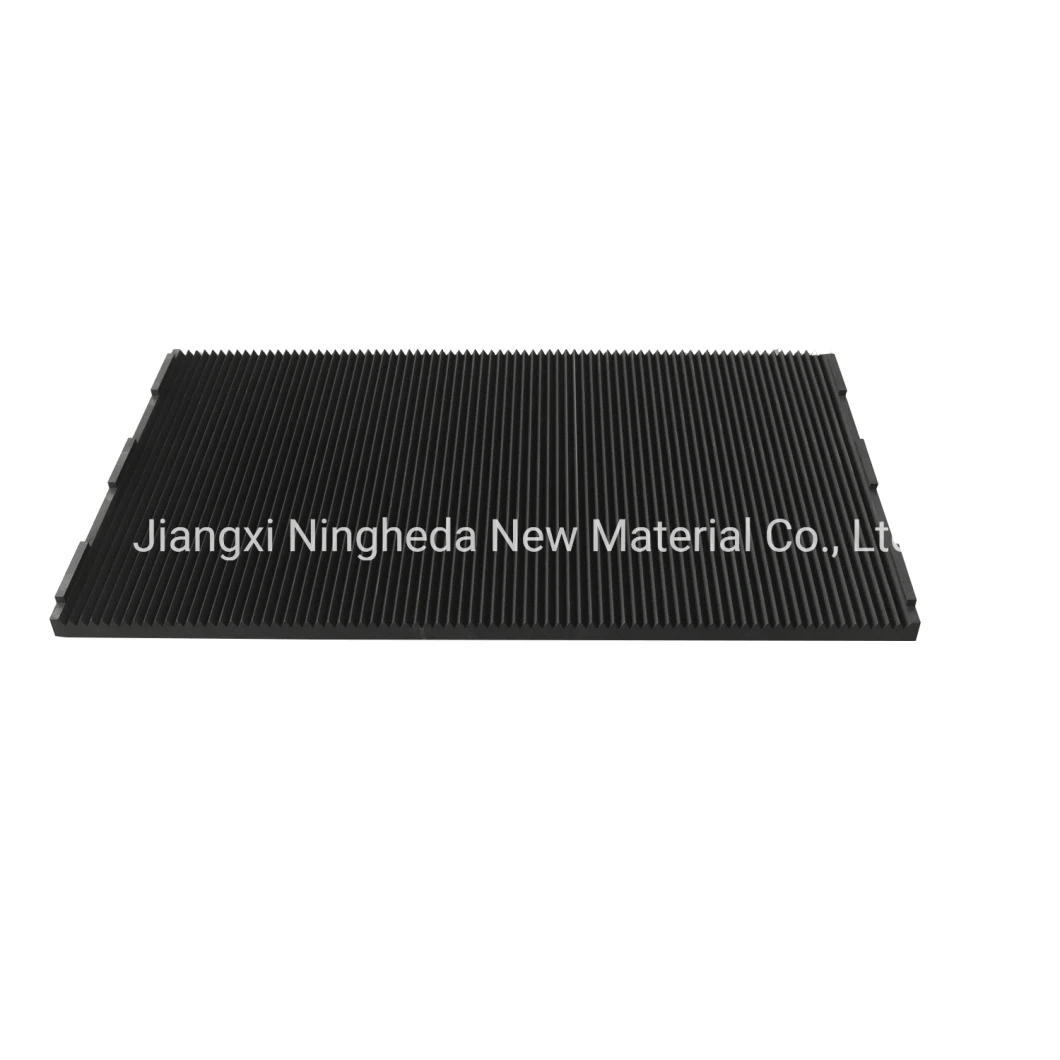

Customized Graphite plate for powder metallugy high temperature sintering

1. High body density, high temperature resistance, high mechanical strength and strong chemical stability.

2. The surface can be treated with anti-oxidation.

3. Corrosion resistance, strong acid and alkali resistance.

4. Excellent thermal shock resistance, electrical conductivity and thermal conductivity.

5. Strong wear resistance and lubrication performance.

6. Long service life.

The main application areas of graphite plate:

1. Widely used in the metallurgical industry as a refractory material.

2. Widely used in the electronics industry, as conductive materials such as electrodes.

3. Can be used as wear-resistant and lubricating materials.

4. Widely used in petroleum, metallurgy and other industries as anti-corrosion materials.

5. Used in centrifugal pumps and other equipment as pump sheet or sealing material.

6. Used in industrial furnaces to make industrial furnace components.

6. Used as an electrolysis board during electrolysis.

- Technical Index

| Type | MSS80 | MSS85 | MSS90 |

| Grain Size (μm) | 25 | 25 | 25 |

| Bulk Density (≥g/cm3) | 1.80 | 1.85 | 1.90 |

| Compressive Strength (≥MPa) | 60 | 70 | 80 |

| Flexural Strength(≥MPa) | 30 | 35 | 40 |

| Porosity(≤%) | 17 | 14 | 10 |

| Specific Resistance(≤μΩm) | 12 | 12 | 12 |

| Ash Content(≤%) | 0.06 | 0.05 | 0.05 |

| Shore Hardness | 50 | 55 | 60 |

- The ash content can be purified to 30ppm according to the requirement.

- The above index data is the standard value, not the guaranteed value.