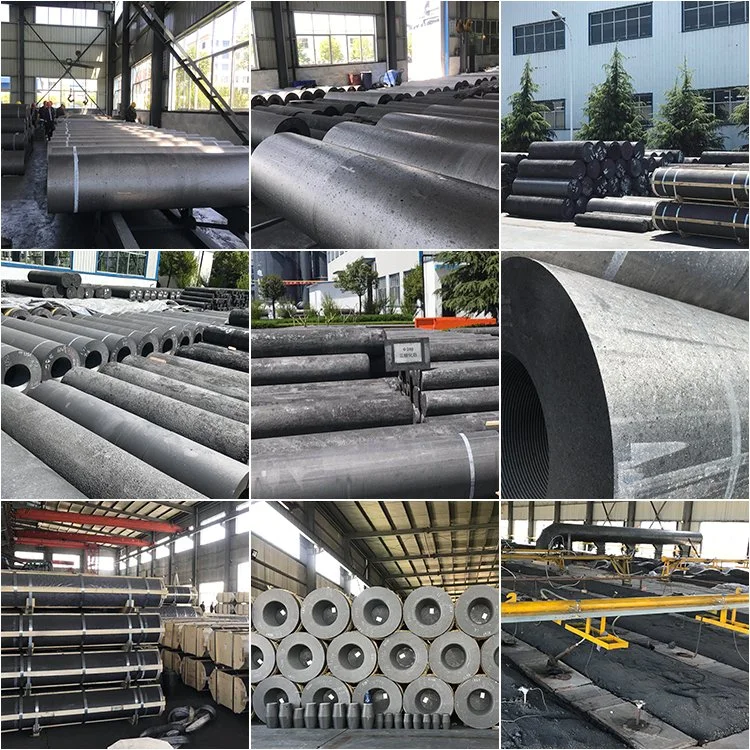

UHP 500mm2400mm Graphite Electrode for Metal Smelting

Company Description:

Rongxing carbon established in 1992, after twenty years development, we has formed our own production system: electrode paste and recarburizers (including anthracite carburant, calcined petroleum coke carburant, graphite recarburizer) are core products, and also produce pre-baked anode, anode scrap, carbon brick coal and petroleum coke.

We are a manufacturer and trading combo,special in the carbon&graphite procuts for 24 years. The main products is EP(electrode paste),GE(graphite eletrode), (CPC)calcined petroleum coke, and also do trading for other carbon and graphite items.

Our carbon and graphite items have passed the testing specific carbon testing according to JB/T6773-2011.We're sure that the material is in striectly accordance to REACH regalation for EU market.

Annual output:50,000tons graphite electrode

200,000tons electrode paste

200,000tons calcined petroleum coke

Product Details

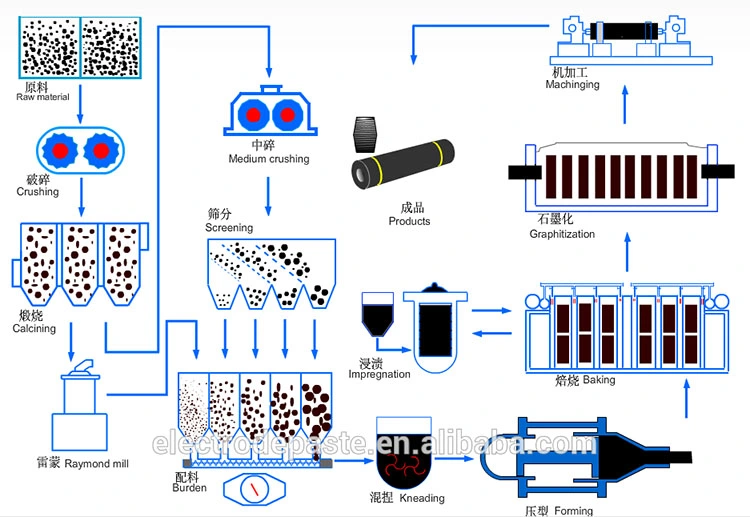

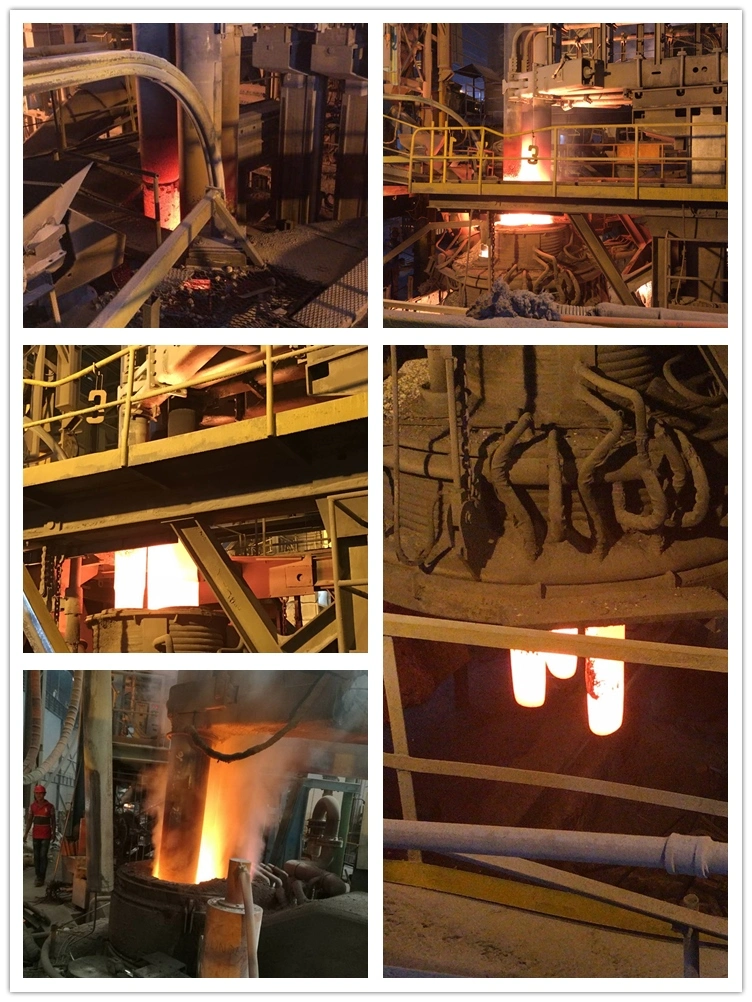

Introduction: graphite electrode, mainly petroleum coke, needle coke as raw material, coal pitch as binder, calcination, ingredients, kneading, molding, baking and graphitization, machining and made, which is released in electric arc furnace in the form of arc conductor of electricity to heat melting furnace charge, graphite electrode with low resistivity,graphite electrode good conductivity, graphite electrode low ash, graphite electrode uniform and graphite electrode compact structure, good oxidation resistance, high mechanical strength, etc.

Category: Regular powder electrode RP, high-power electrode HP,

ultra-high-power electrode UHP...

Uses: used in steel, metallurgy industries.

Length: 1800-2700mm

Diameter: 200-600mm

Property

1. Low resistivity

2. Good conductivity

3. Low ash

4. Compact and uniform structure

5. Good oxidation resistance

6. Mechanical strength

Specification:

| Item | Unit | Graphite Electrode | ||||

| RP | HP | UHP | ||||

| φ300-φ800mm | φ300-φ800mm | φ300-φ500mm | φ550-φ800mm | |||

| Typical Value | Typical Value | Typical Value | Typical Value | |||

| Resistivity | Electrode | μΩm | 7.0-10.0 | 5.8-6.6 | 4.5-5.8 | 4.6-5.8 |

| Nipple | 4.0-4.5 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | ||

| Modulus of Rupture | Electrode | Mpa | 8.0-10.0 | 10.0-13.0 | 10.0-14.0 | 10.0-14.0 |

| Nipple | 19.0-22.0 | 20.0-23.0 | 20.0-24.0 | 22.0-26.0 | ||

| Young's Modulus | Electrode | GPa | 7.0-9.3 | 8.0-12.0 | 9.0-13.0 | 10.0-14.0 |

| Nipple | 12.0-14.0 | 14.0-16.0 | 15.0-18.0 | 16.0-19.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.53-1.56 | 1.64-1.68 | 1.68-1.74 | 1.70-1.74 |

| Nipple | 1.70-1.74 | 1.75-1.80 | 1.78-1.82 | 1.80-1.84 | ||

| CTE (100-600ºC) | Electrode | 10-6/ºC | 2.2-2.6 | 1.6-1.9 | 1.1-1.4 | 1.1-1.4 |

| Nipple | 2.0-2.5 | 1.1-1.4 | 0.9-1.2 | 0.9-1.2 | ||

| Ash | % | 0.5 | 0.3 | 0.3 | 0.3 | |

Current load and current density:

| Diameter | RP | HP | UHP | |||

| mm | Current Load (A) | Current Density(A/cm³) | Current Load (A) | Current Density(A/cm³) | Current Load (A) | Current Density(A/cm³) |

| 200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 | ||

| 225 | 6100-8600 | 15-21 | 6500-10000 | 18-25 | ||

| 250 | 7000-10000 | 14-20 | 8000-13000 | 18-25 | 8100-12200 | 20-30 |

| 300 | 10000-13000 | 14-18 | 13000-17400 | 17-24 | 15000-22000 | 20-30 |

| 350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

| 400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

| 450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-27 |

| 500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

| 550 | 32000-40000 | 13-16 | 37000-57000 | 15-23 | 42000-66000 | 17-26 |

| 600 | 38000-47000 | 13-16 | 44000-67000 | 15-23 | 49000-76000 | 17-26 |

Graphite electrode and furnace matching ref.

| Capacity of furnace | EAF furnace | LF furnace |

| 5 ton | 250RP | |

| 10 ton | 350HP | 250RP |

| 20 ton | 400HP | 300HP |

| 30 ton | 450HP | 350HP |

| 50 ton | 500UHP | 350HP |

| 75 ton | 550UHP | 350UHP |

| 100 ton | 600UHP | 450UHP |

| 150 ton | 700UHP | 450UHP |

Product Processing

Customer negotiation

Contact