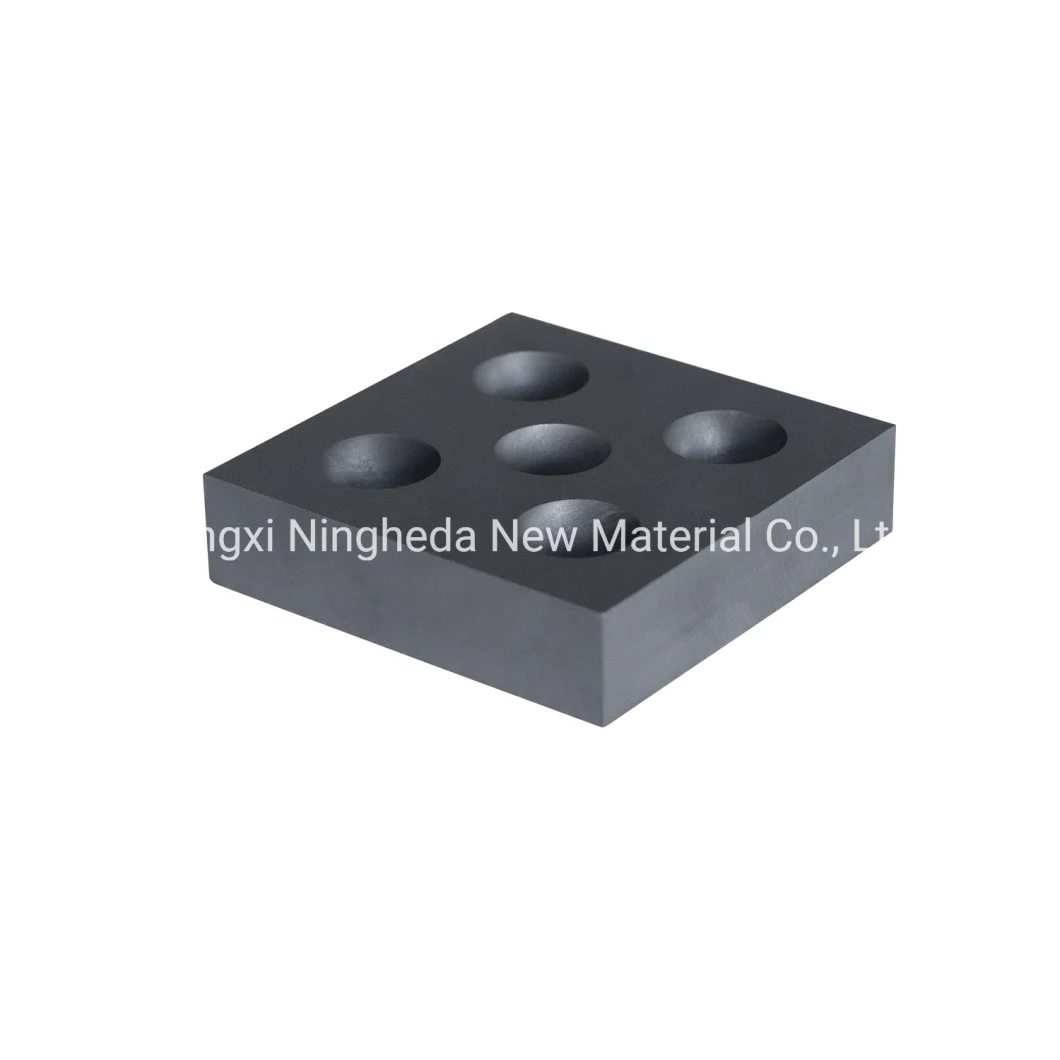

High quality graphite blowing mould for glass fiberglass production industry

The conductivity of

graphite has good electrical conductivity. With increasing temperature, the electrical conductivity increases. In this regard, the temperature coefficient of resistance of the graphite, in contrast to metals, graphite negative.

Electrical resistivity

resistivity-physical quantity characterizing a substance prevent the passage of electric current. The higher the density of graphite, the lower resistivity.

Measure: Ohm * m

Thermal conductivity

The thermal conductivity of graphite is higher than many metals, and decreases as the temperature increases. The thermal conductivity of the graphite varies depending on the treatment temperature.

Measure: W / (m * K)

Heat Resistance

Graphite does not melt but sublimes at a temperature of 3900 ° K and withstands harsh temperature changes.

Wettability of the

graphite is not wetted by most molten metals and molten glass.

Oxidizability

In the presence of excess air Graphite begins to oxidize at 750 ° K. Graphite is not soluble in solvents and inorganic organic origin, does not interact with many acids, alkalis and salts.

Mechanical strength

graphite Tensile strength, compressive and bending strength increases with increasing temperature up to 2700 ° C, and only then begins to decline.

Mechanical strength values of graphite characterize such as tensile strength in bending and compression strength . With increased density, both of these quantities are increased. Unit: MPa.

Purity

All graphites contain in its structure in greater or lesser amounts of minerals (ash). Special graphite purification technology allows to reduce the ash content to 10 -4 -10 -5 wt% with ash content of 0.5% in the starting materials.

Machinability

Graphite is well machinable; its properties and structure allow to produce products of complex shapes with tight tolerances and high precision. The combination of such a large number of positive properties in one material only predetermined its widespread use.

The anisotropy of physical properties

Physical properties of graphite depend on the orientation of the grains of coke of which recipe is constituted. In turn, the physical properties of graphite affects the way of pressing. Graphite, pressing is carried out by extrusion, characterized by a pronounced anisotropy of properties. Grain oriented perpendicular to the direction of pressing. Graphite manufactured by stamping and isostatic pressing, a more isotropic than those produced by extrusion.

| Type | MSS80 | MSS85 | MSS90 |

| Grain Size (μm) | 25 | 25 | 25 |

| Bulk Density (≥g/cm3) | 1.80 | 1.85 | 1.90 |

| Compressive Strength (≥MPa) | 60 | 70 | 80 |

| Flexural Strength(≥MPa) | 30 | 35 | 40 |

| Porosity(≤%) | 17 | 14 | 10 |

| Specific Resistance(≤μΩm) | 12 | 12 | 12 |

| Ash Content(≤%) | 0.06 | 0.05 | 0.05 |

| Shore Hardness | 50 | 55 | 60 |

- The ash content can be purified to 30ppm according to the requirement.

- The above index data is the standard value, not the guaranteed value.