Our Company:

Our main product is graphite electrode are manufactured with high quality raw materials including petroleum cokes,needle cokes and coal tar pith through the production process ofcalcining,crushing,screening,dosing,kneading,extruding,baking,impregnation,machining,

our products are characteried by superior compact structure.

UHP Graphite Electrode:

Item | Unit | Nominal Diameter mm | ||

≤ Φ400 | ≥ Φ450 | |||

Resistivity | electrode | μ Ω·m | 4.0--5.3 | 4.0-5.5 |

nipple | 3.8 | 3.8 | ||

Bending Strength | electrode | Mpa | ≥ 12.0 | ≥ 12.0 |

nipple | ≥ 24.0 | ≥ 24.0 | ||

Elastic Modulus | electrode | Gpa | ≤ 14.0 | ≤ 14.0 |

nipple | ≤ 18.0 | ≤ 18.0 | ||

Bulk Density | electrode | G/cm3 | ≥ 1.68 | ≥ 1.68 |

nipple | ≥ 1.75 | ≥ 1.75 | ||

C.T.E (100~600ºC) | electrode | 10-6/ºC | ≤ 1.3 | ≤ 1.3 |

nipple | ≤ 1.2 | ≤ 1.2 | ||

ASH | electrode | % | ≤ 0.3 | ≤ 0.3 |

nipple | ≤ 0.3 | ≤ 0.3 | ||

HP Graphite Electrode:

Item | Unit | Nominal Diameter mm | ||

≤ Φ400 | ≥ Φ450 | |||

Resistivity | electrode | μ Ω·m | ≤ 6.2 | ≤ 6.5 |

nipple | ≤ 4.5 | ≤ 4.5 | ||

Bending Strength | electrode | Mpa | ≥ 11.5 | ≥ 11.0 |

nipple | ≥ 22.0 | ≥ 22.0 | ||

Elastic Modulus | electrode | Gpa | ≤ 12.0 | ≤ 12.0 |

nipple | ≤ 16.0 | ≤ 16.0 | ||

Bulk Density | electrode | G/cm3 | ≥ 1.66 | ≥ 1.66 |

nipple | ≥ 1.73 | ≥ 1.73 | ||

C.T.E (100~600ºC) | electrode | 10-6/ºC | ≤ 1.8 | ≤ 1.8 |

nipple | ≤ 1.5 | ≤ 1.5 | ||

ASH | electrode | % | ≤ 0.3 | ≤ 0.3 |

nipple | ≤ 0.3 | ≤ 0.3 | ||

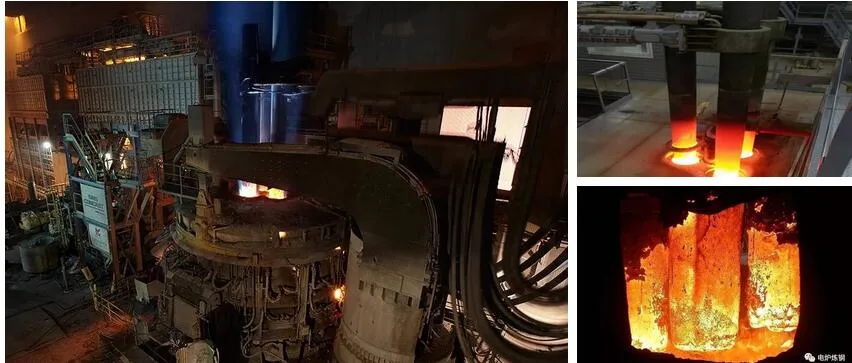

Mainly used for the electric arc furnace to smelt the molten steel and used for the refining furnace such as AOD VOD LF furnaces in the steel and non-ferrous me.

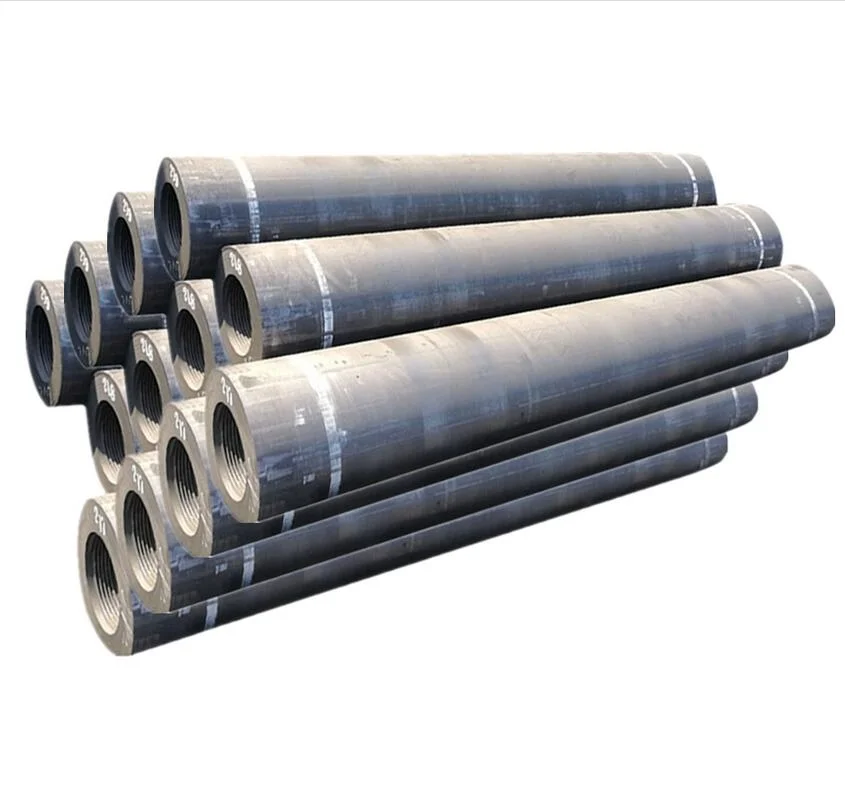

Graphite electrode is made of high quality calcined petroleum coke,imported needle coke and modified coal asphalt,the grade are RP,HD(impregnation),HP and UHP graphite electrodes,the specification is Ø75-700mm.

Graphite electrode produced by our company has the advantages of low resistivity,high electrical conductivity and thermal conductivity,good oxidation resistance,good thermal shock resistance,high mechanical strength,easy to machine,etc. Graphite electrode is widely used to smelt the steel,alloy steel and other metal or nonmetal material in electric arc furnace.

Detailed Images:

The electrodes carry the electricity that heats electric arc furnaces, the vast majority steel furnaces. They are made from petroleum coke after it is mixed with petroleum pitch, extruded and shaped, then baked to sinter it, and then graphitized by heating it above the temperature (3000 °C) that converts carbon to graphite. They can vary in size up to 11 ft. long and 30 in. in diameter.

Usage: An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

Packing & Delivery:

cardboard box for RP HP HD SHP UHP, grade graphite electrode for arc furnaces with nipples.

Advantages of Graphite electrode:

1. Reduce graphite electrodes lateral oxidation rate.

2. Lessen graphite electrodes consumption rate by 15%~20%.

3. Improve graphite electrodes cost efficiency.

4. It is a more cost-effective solution through reducing graphite electrodes purchasing cost by 10%~15%.

5. It is a production efficiency improving solution through reducing risk of graphite electrodes breakage and falling down.

Quality System Control:

- Management delegates and quality inspection department organize internal examine

- every year to supervise and check system running status.

- Second party inspection is carried out by end user.

- Third party inspection is carried out by certificaiton authority

- Packing and logistic is farmed out to other company, and strictly execute as per Contract items.

- We have specific after-sales service to check our product performances

FAQ

1. Are you a trader or manufacturer?

We are manufacturer, we have our own factory.

2. Can you accept OEM or ODM?

Of course, logo is also acceptable.

3. What is the delivery time?

About 10-20 days after signing the contract.

4. What is your payment term?

T/T, L/C, D/P, Paypal, West Union and others.

Service

1. Timely Response: Quick response emails and solutions to your inquiry in 24 hours.

2. Free Sample: Sample and trial orders are accepted for the quality evaluation.

3. Shorter Delivery Time: Book the earliest vessel or plane to guarantee the delivery time.

4. Professional Service: Provide high temperature solutions, installation & technology service.

Notice:

Please note that the price on Made-in-China is a rough price.

The actual price will depends on raw materials, exchange rate ,wage and your order quantity .

Hope to cooperation with you,Thanks !