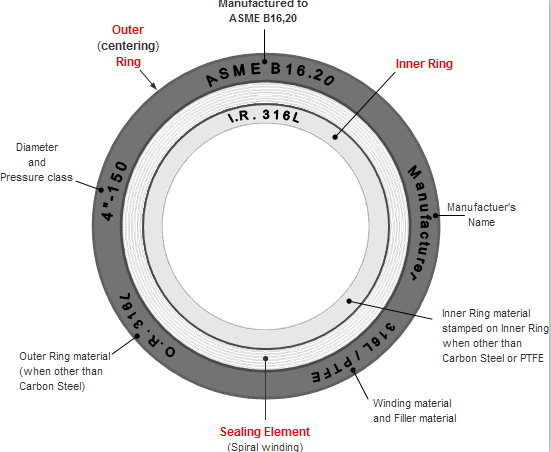

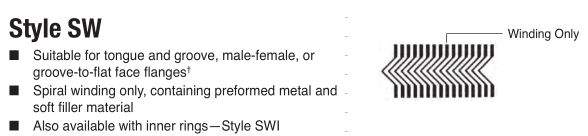

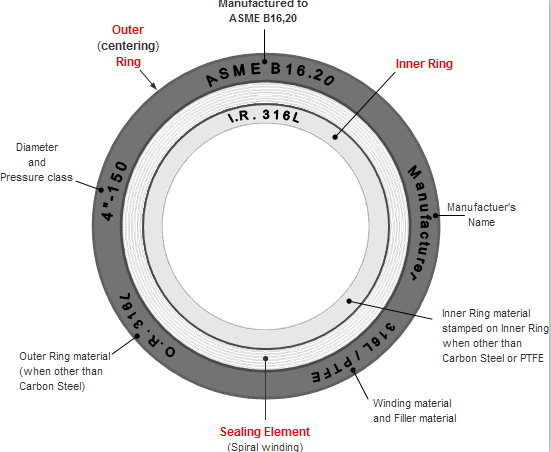

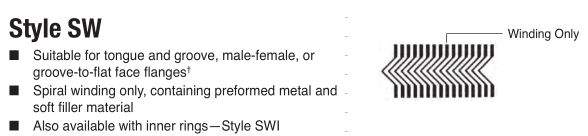

Spiral wound gaskets-made with an alternating combination of formed metal wire and soft filler materials form a very effective seal when compressed between two flanges.A v-shaped crown centered in the metal strip acts as a spring, giving gaskets greater resiliency under varying conditions. Filler and wire material can be changed to accommodate different chemical compatibility requirements.Fire safety can be assured by choosing flexible graphite as the filler material. If the load available to compress a gasket is limited, gasket construction and dimensions can be altered to provide an effective seal.A spiral wound gasket may include a centering ring, an inner ring or both. The outer centering ring centers the gasket within the flange and acts as a compression limiter,while the inner ring provides additional radial strength.The inner ring also reduces flange erosion and protects the sealing element.Resiliency and strength make spiral wound gaskets an ideal choice under a variety of conditions and applications. Widely used throughout refineries and chemical processing plants, spiral wound gaskets are also effective for power generation, pulp and paper, aerospace, and a variety of valve and specialty applications.

Place of Origin:CN;Zhejiang

Brand Name:Yiyu

Material:Graphite

Shape:Flat Gasket

Standard or Nonstandard:Standard

Name:Flexible graphite spiral wound gasktet

Standard:ASME B16.20

Certificate:ISO9001:2008 Type:Basic type , Inner ring , Outer ring , Inner and out ring

Color:Yellow with black

Usage:Gasket Material

Quality:High Level

Temperature:-196 - 700 Degree (not higher than 600 degree in oxidic medium)

Feature:Temperature Resistance and Pressure Resistance

Place of Origin:CN;Zhejiang

Brand Name:Yiyu

Material:Graphite

Shape:Flat Gasket

Standard or Nonstandard:Standard

Name:Flexible graphite spiral wound gasktet

Standard:ASME B16.20

Certificate:ISO9001:2008 Type:Basic type , Inner ring , Outer ring , Inner and out ring

Color:Yellow with black

Usage:Gasket Material

Quality:High Level

Temperature:-196 - 700 Degree (not higher than 600 degree in oxidic medium)

Feature:Temperature Resistance and Pressure Resistance